This circuits can help begginers to understand a transistor and use it for their ciruits. i will explain the general working of the transistor as a swithch and finally will give you few ideas of how all i used it.

Binary Output with a transistor:

1) Design a circut which allows a PIC processor to drive an LED array. This LED array has the following properties:

Vf @ 80mA = 10.2V ( six red LEDs are placed in series, giving 6 x 1.7V = 10.2V)

Assume that the PIC is only capable of driving 10mA at 5V.

Step 1. Find a transistor which can withstand 80mA.

110 < hFE < 450 ——>meaning you can count on a gain of atelast 300

max IC (Sat) = 200mA ——>meaning this can take 200mA. 80mA is quite small rite.

VCE(Sat) = 0.25V ——>a rough estimate of VCE at saturation

VCEO = 45V ——->meaning this transistor can take +45V when turned off

Step 2: Find a power supply bigger than 10.2V. Arbitrarilly assume a +24 supply.

Step 3: Find Rc to limit the current to 80mA

RC =( 24V-10.2V-0.25V)/ 80mA = 170 ohms

Step 4: Find RB to saturate the transistor. At the lowest gain, to put you just at the point of saturation,

Ib = ICE/hfe = 80mA /150 = 534uA —->150 is typical Hfe for BC107B in datasheet*

RB = 5V-0.7V/534uA = 32kohm

Pick R smaller than this to assure you saturate this stage. Let R = 10k.

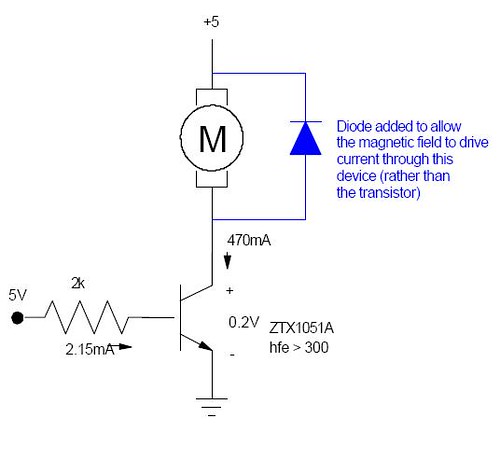

In this pic that i got from a random site kindly overlook the ZTX1051A transistor with Hfe>300. i have shown you calculations for BC107.

In this pic that i got from a random site kindly overlook the ZTX1051A transistor with Hfe>300. i have shown you calculations for BC107.

000000000000000000000000000000000000000000000000000000000000000000000

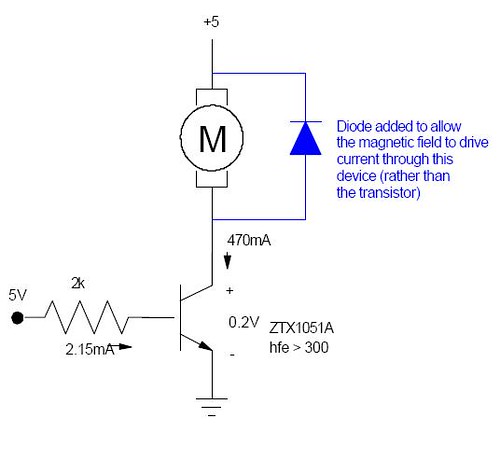

2) Design a circuit whichuses a single output from the PIC processor, and allows a PIC processor to drive this motor in the clockwise direction at either 0% speed (0V) or 100% speed (+5V). Assume the motor draws 470mA at +5V.

Step 1: Pick a transistor. I'll stick with a BC107 because I like this transistor.

Step 2: Add the motor to the collector. You don't need a current limiting resistor since the motor's armature resistance and back EMF limit the current to 470mA @ 5V.

Step 3: Add RB to saturate the transistor. Worst case, when the gain is minimum (300) and you're just at the point of saturation:

IB = ICE/Hfe = 470mA/150 = 3.14mA

RB = 5V-0.7V/3.14mA = 5.48kohm

Step 4: Just to make sure that you saturate the transistor, make Rb smaller than this. Let RB = 2k.note: The inductance in the motor stores energy in a magnetic field. When the current is turned off (the transistor turns off) the energy in the field has to go somewhere. To save the transistor, place a diode across the motor to allow the collapsing field to drive current through the diode – saving the transistor

again the ZTX1051A is replaced by BC107 and the current at 2k at base resistance is 3.14mA.

again the ZTX1051A is replaced by BC107 and the current at 2k at base resistance is 3.14mA.

000000000000000000000000000000000000000000000000000000000000000000000

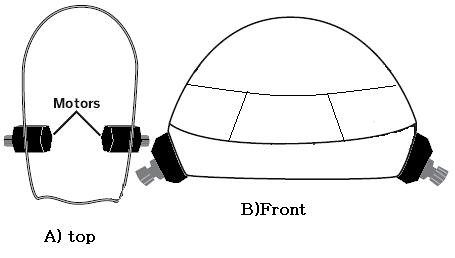

3) Design a circuit which can drive the motor forward and in reverse using transistors:This is the transistor version of my ULN2003 H-Bridge

You can use the same circuit as before, only add another NPN and two more PNP transistors. The equations work out

the same for each transistor:

NPN:BC107

OFF: put the input to 0V. This assures that 0A flow through the diode.

ON: make RB = 2k to saturate this transistor when 470mA flow though it.

IB > 470mA/Hfe = 3.14mA

RB < 5V-0.7V/1.57mA = 5.48kohm

Let RB = 2k.

PNP: BC177(since I picked a transistor with the same gain (Hfe or b)

OFF: put the input to +5V. This assures there is no potential across the base diode and no current flows.

ON: Make RB = 2k to saturate this transistor when 470mA flows through it.

IB > 470mA/Hfe = 3.14mA

RB < 5V-0.7V/3.14mA =5.48k

Let RB = 2k

That will do…..

000000000000000000000000000000000000000000000000000000000000000000000

MY IDEAS TO USE TRANSISTORS AS SWITCH:

1) I connected my local FM radio reciever to my parallel port. There are only two switches to operate it. one for selecting channel and the other for reset . just connect it this way below and you can write a code in VB or C to address the ports and to scan or reset.

The two black thigs are the switches.. just pic the two sides which the switch shorts on pressing and make this combination and get your electronic switch working.

2) I have connected my calculator and microcontroller using the same concep.. I will put those pics later as my friend is havin the digi as of now!!

Cheers trying the circuits. Keep giving your coments plas (it will cheer me up!!) –Madan

In this pic that i got from a random site kindly overlook the ZTX1051A transistor with Hfe>300. i have shown you calculations for BC107.

In this pic that i got from a random site kindly overlook the ZTX1051A transistor with Hfe>300. i have shown you calculations for BC107. again the ZTX1051A is replaced by BC107 and the current at 2k at base resistance is 3.14mA.

again the ZTX1051A is replaced by BC107 and the current at 2k at base resistance is 3.14mA.